As systems become more data-centric, monitors in industrial, iot, home medical wearables, fitness and health are experiencing explosive growth. These data-centric systems are increasingly demanding more features and lower power consumption. This trend is driven by intelligent systems that actively monitor a person or environment and make predictive responses, including alarms, actions, or recommended actions. The response is only as good as the data provided, which is why these systems need to collect large amounts of high-precision data through a single sensor or wireless sensor network.

The challenge for sensor application design engineers is to require sensor modules that take up minimal board area while maintaining high accuracy and extending battery life. In order to solve this challenge, there are two responses: one is to maximize the energy efficiency ratio of component and system operation, and the other is to invest in research and development of new low-power architectures. The first approach focuses on developing systems that rely on batteries to work longer and provide greater responsiveness and accuracy, which is expected to help designers achieve their goals in the short term.

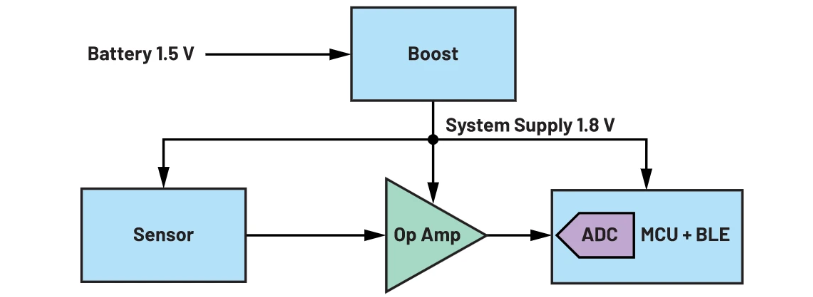

Figure 1. The design used by the current AI system is shown in the sensor block diagram below

Maximize power efficiency

Figure 1 above shows a typical block diagram for sensor applications. The four basic modules of the solution are system power supply, sensor, sensor signal amplification and signal processing. Choosing the right device is crucial to maximize the battery life of the sensor module. Below we take a closer look at each module to see what can be done to improve power efficiency and provide more accurate measurements.

Sensor selection

The first consideration is sensors. There are two main types of sensors used in today's sensor modules: single-ended sensors and differential sensors. Single-ended sensors include electrochemical sensors for blood sugar detection, gas sensors, and wearable medical sensors. Differential sensors typically use instrument amplifiers, and applications include industrial pressure or force sensors, industrial temperature sensors, and air-inline and congestion sensors in medical applications. These are common in medical insulin pumps and in-line air detectors.

The more common type of sensor is the electrochemical sensor. These are low-power sensors, including blood sugar sensors, which millions of people with diabetes use to control their blood sugar levels. Other applications include gas sensors (e.g., carbon dioxide (CO2) sensors), water quality (conductivity, pH, etc.) sensors, alcohol sensors for oil degradation, and sensors for detecting explosives.

Most applications of electrochemical sensors are portable and battery-powered applications. While CO2 sensors in homes typically last five to seven years, they may need to be replaced with new batteries about every six months to a year. To extend battery life, manufacturers use the latest low-power devices that draw minimal current from the battery.

Let's take a closer look at a specific type of electrochemical sensor, the ethanol sensor, and understand how it works.

Working principle of ethanol sensor

The ethanol sensor used in Figure 1 is an amperometric gas sensor that produces a current proportional to the volume fraction of the gas. It is a three-electrode device where ethanol is measured at the working (or detecting) electrode (WE). The opposite electrode (CE) completes the circuit, while the reference electrode (RE) provides a stable electrochemical potential in the electrolyte, which does not come into contact with ethanol. For SPEC sensors, a bias voltage of +600mV is applied to the RE.

Many electrochemical sensors require a fixed bias to function properly, which puts an additional burden on battery life. Now let's consider the power requirements of the system.

Power requirements

The power budget of the system and its battery capacity ultimately determine the operating life of the sensor. The typical goal of a small-size battery-powered solution is to use a single 1.5V battery. Using a single battery reduces capacity, which affects the working life of the sensor. So, what can be done to optimize the working life of a single battery?

When fully charged, that is, at the beginning of its life, a single battery is 1.5V. This voltage gradually decreases over time, reaching 0.9V at the end of its life. To maximize the life of a single battery, the application must run between 0.9V and 1.5V for maximum application operating time. Since other system devices operate at 1.8V, a DC-DC boost converter must be selected that maximizes operating and standby current efficiency and can operate in the 0.9V to 1.5V range.

Having a 95% high efficiency is not the only consideration for efficient power conversion. The boost regulator must also be able to operate efficiently over a wide current range, thereby reducing static current (IQ) and heat dissipation during operation. Applications spend most of their time in standby mode, so boost converters must be highly efficient in light standby to extend battery life. The off feature reduces current consumption to the nA range by shutting down part of the circuit, which also significantly reduces power consumption.

Signal chain solutions

The output signal generated by the sensor is usually very weak, only a few uV, while the analog-to-digital converter needs a V-level signal. Therefore, the selection of low-power, high-precision amplifiers is the second most important consideration in the design.

Low power amplifiers have two important aspects - current consumption and operating voltage, as many sensors require bias current to maintain accuracy. This requires the application's sensor to be partially turned on to maintain an accurate reading. In addition, low operating voltages from 0.9V to 1.5V support single battery power without the need for a boost converter.

In general, the disadvantage of choosing a low-power amplifier is lower accuracy. However, there are low-power amplifiers that maintain a high level of accuracy even at low operating currents and voltages. Some of the characteristics of precision amplifiers include submicrovolt (µV) input offset voltage, voltage drift at the nV/°C level, and input bias current at the pA level.

A low-power microcontroller, combined with an integrated ADC, provides a low-power sensor solution that maximizes battery life while keeping applications small.

Measurement of ethanol sensor solutions

In addition to device-level improvements, the system architecture can be optimized to achieve lower power consumption at the same level of precision measurement. To demonstrate this, we will provide two experimental measurements of an ethanol sensor solution using similar devices, and one theoretical measurement of a future sensor solution that shows the benefits of power savings.

The experiment uses the devices listed below, which have the same duty cycle for ethanol electrochemical sensor measurements.

● SPEC electrochemical ethanol sensor

● MAX40108 1V precision operational amplifier /1.8V operational amplifier

● MAX17220 0.4-5.5V nanoPower synchronous boost converter that provides True Shutdown™

● MAX6018A 1.8V precision, low-voltage differential reference voltage source

● MAX32660 1.8V ultra-low power Arm® Cortex®-M4 processor

● Single 1.5V AA battery

Figure 2. The figure below shows a traditional 1.8V sensor system solution

Traditional 1.8V system

The 1.8V system solution uses a single battery to provide 1.8V system power to ethanol sensors, operational amplifiers, and microprocessors with ADCs using an efficient boost converter. The duty cycle of 0.1% activity is controlled by a microcontroller, which wakes up to take measurements and then goes back to sleep mode.

Sensors in standby mode maintain power to sensors, operational amplifiers and microcontrollers in sleep mode using a boost converter. In standby mode, the system consumes 150.8µA of current. During the active state, the microcontroller wakes up and takes sensor measurements. In the active state, the system consumes 14mA for a short time. The active state accounted for only 0.1% of the time, and the average current combined in active and standby mode was calculated to be 164µA, which is typical for real-world sensor applications.

Figure 3. The next generation 1V amplifier sensor solution is shown below

1V amplifier system

In the 1V amplifier solution, both the SPEC ethanol sensor and the MAX40108 1V op amp are connected directly to the battery. This requires an amplifier that can operate at voltages as low as 0.9V, maintain high accuracy levels, and maximize the life of a single battery.

The rest of the circuit is similar to the boost regulator that powers the microcontroller and supports the 1.8V circuit. In this configuration, the current is significantly reduced to 81.9µA, a 45% reduction. The average current is reduced to 95.7 µA, a decrease of 41.79%. As aresult, the battery life of a system using the MAX40108 1V op amp is almost double that of a conventional system.

Figure 4. The block diagram below shows the future 1V sensor system solution

Future 1V signal chain system

In this future 1V signal chain solution, the amplifier, ADC and microcontroller all operate at voltages as low as 0.9V while maintaining a high level of precision. This allows the entire signal chain solution to be powered by a single battery, eliminating the need for a boost converter and maximizing battery life for sensor solutions.

Conclusion

The demand for smarter AI systems is growing, so is the need for sensors with additional capabilities, higher accuracy and longer life. Sensors must provide small scale solutions that can be worn or networked to determine the health of a person, production plant, building or city, enabling systems to be proactive rather than reactive. Going one step further, for those who benefit from this new generation of systems, proactive response improves health, reduces costs, increases productivity, and enhances safety.

In sensor networks that enable AI systems, innovation is happening at many different levels. IC manufacturers, in particular, are developing lower-power sensor building blocks to help today's engineers create smarter, more efficient systems for tomorrow.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.