Traction inverters are the main component that consumes battery power in electric vehicles (EVs), with power levels up to 150kW or higher. The efficiency and performance of traction inverters directly affect the driving range of electric vehicles after a single charge. Therefore, in order to build the next generation of traction inverter systems, silicon carbide (SiC) field-effect transistors (FETs) are widely used in the industry to achieve higher reliability, efficiency and power density.

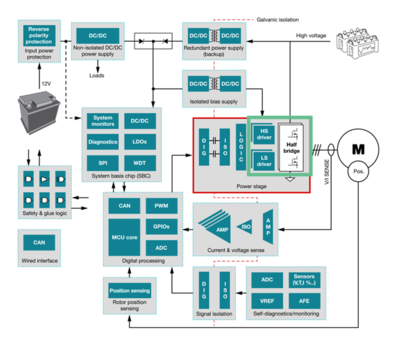

The isolated gate driver integrated circuit (IC) shown in Figure 1 provides electrical isolation from low voltage to high voltage (input to output), drives the high side and low side power modules of each phase of the inverter, and monitors and protects the inverter from various failures. According to Automotive Safety Integrity Level (ASIL) functional safety requirements, gate driver ics must comply with ISO 26262 standards, ensuring failure detection rates of ≥99% and ≥90% for single and potential failures, respectively.

In this article, we will highlight the technical advantages of real-time variable gate drive strength, a new feature that allows designers to optimize system parameters such as efficiency (which affects EV range) and SiC overshoot (which affects reliability).

Figure 1: electric vehicle traction inverter block diagram

Increase efficiency with real-time variable grid drive strength

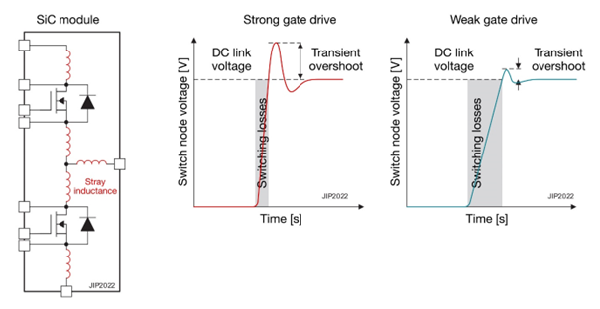

The gate driver IC must conduct the SiC FETs as efficiently as possible while minimizing switching losses. The ability to control and vary the strength of the gate drive current reduces switching losses, but at the cost of increasing transient overshoot at the switching node during switching. Changing the gate drive current can control the switching speed of the SiC, as shown in Figure 2.

Figure 2: Control SiC switching speed by varying gate driver IC drive strength

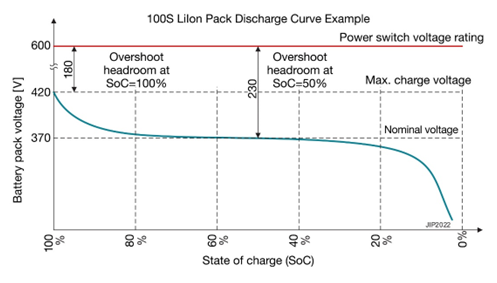

Real-time variable gate drive current enables transient overshoot management and design optimization of the entire high-voltage battery energy cycle. Batteries that are fully charged and in a 100% to 80% charged state should use a lower gate drive strength to keep the SiC voltage overshoot within limits. With the reduction of battery power from 80% to 20%, the use of higher gate drive strength reduces switching losses and improves traction inverter efficiency, which is true for 75% of the charge cycle, so the improvement in system efficiency is very significant. Figure 3 shows the typical transient overshoot in relation to the peak voltage and charge state of the battery.

Figure 3: Relationship between transient overshoot and peak battery voltage and charge state

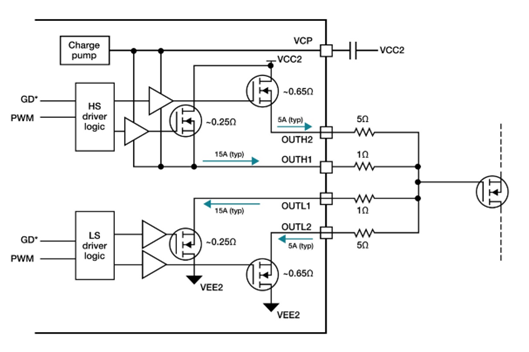

The UCC5880-Q1 is a maximum 20A SiC gate driver with a variety of protection features for traction inverters in automotive applications. Its gate drive strength ranges from 5A to 20A and can be adjusted with a 4MHz bidirectional serial peripheral interface SPI bus or three digital input pins. Figure 4 shows the implementation of the double separation output to achieve variable grid drive strength.

Figure 4: Dual output separate grid drive structure of UCC5880-Q1

Evaluate power level switches using DPT

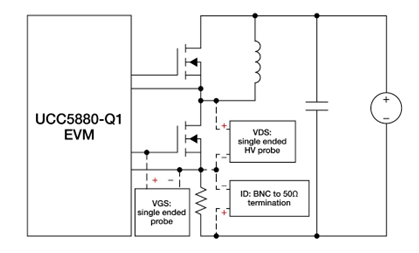

The standard method for evaluating the performance of power level switches in traction inverters is the double pulse test (DPT), which can close and disconnect SiC power switches at different currents. By changing the switching time, the SiC on and off waveforms under operating conditions can be controlled and measured, helping to evaluate efficiency and SiC overshoot, which can affect reliability. Figure 5 shows the connection diagram of a variable strength gate driver with a low side DPT setup for the UCC5880-Q1 and a SiC half-bridge.

Figure 5: Low side DPT block diagram

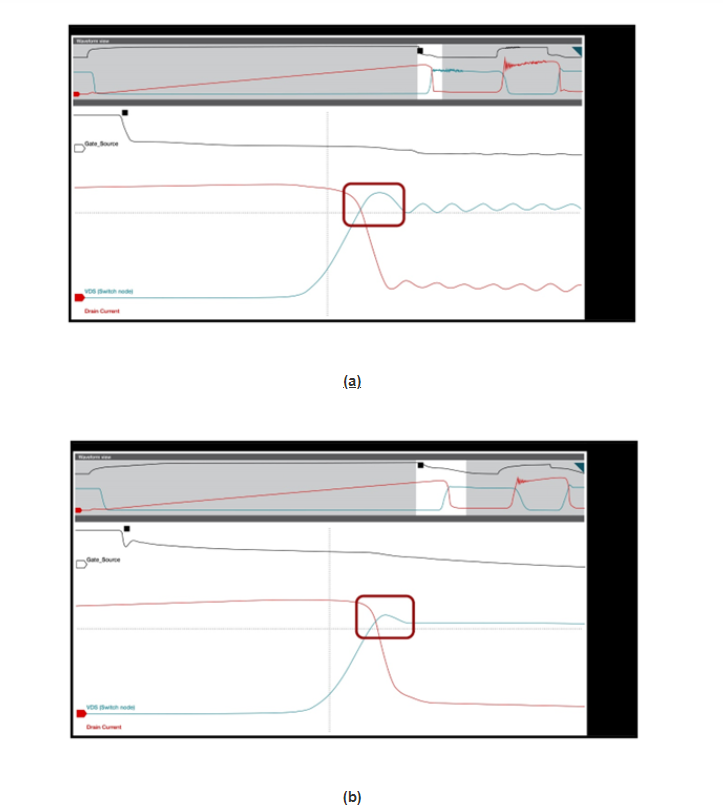

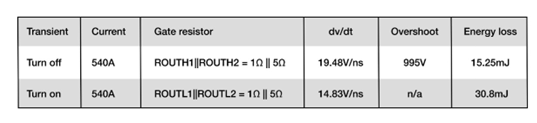

The results in Table 1 show how a SiC gate driver with variable strength can help control overshoot while maximizing efficiency and optimizing thermal performance. EON and EOFF are the energy loss of the switch on and off respectively. VDS,MAX are the maximum voltage overshoot, and TOFF and TON dv/dt are the switching speeds of VDS during on and off, respectively.

Table 1: DPT summary (800V bus, 540A load current, highest to lowest grid drive from left to right)

Relief overshoot

The waveform in Figure 6 shows the effect of variable gate drive strength on SiC overshoot, as the UCC5880-Q1 gate drive resistance and drive strength are controlled in real time. Power stage overshoot is mitigated by using a lower gate drive (SiC off).

Figure 6: Effect of real-time variable grid drive strength on SiC overshoot: SiC strong drive turn-off (a); SiC Weak Drive Off (b)

Table 2 lists the actual measurements used for comparison. Depending on the system parasitic effects and noise control objectives, you can trade off between overshoot, dv/dt, and switching losses accordingly.

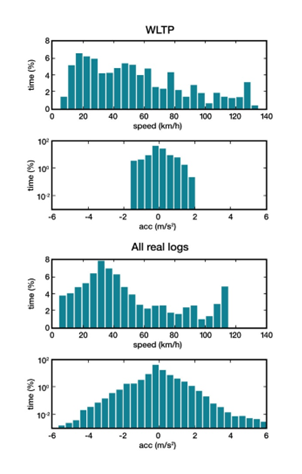

Extended range

When using the UCC5880-Q1's powerful gate drive control features to reduce SiC switching losses, the efficiency gains can be significant, depending on the power level of the traction inverter. As shown in Figure 7, modeling using the Globally Harmonized Light Vehicle Test Procedure (WLPT) and actual driver range speed and acceleration shows that SiC power-level efficiency gains of up to 2% can be achieved, equivalent to an additional 11 km of driving range per battery. Those 11 kilometers could be the difference between consumers finding charging points or getting stuck on the road.

Figure 7: WLPT and real range speed and acceleration histograms

The UCC5880-Q1 also includes SiC gate voltage threshold monitoring, which performs threshold voltage measurements each time the EV is kettled to start over the life of the system, and provides power switch data to the microcontroller for predicting power switch failures.

Peroration

With the power level of electric vehicle traction inverters approaching 300kW, there is an urgent need for greater reliability and greater efficiency. Selecting a SiC isolated gate driver with real-time variable gate drive strength helps to achieve this goal. The UCC5880-Q1 comes with design support tools, including evaluation boards, user guides, and functional safety manuals to assist you with your design.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.