According to IOT Analytics, the global predictive maintenance market will reach $6.9 billion in 2021 and is expected to reach $28.2 billion in 2026. "Under the booming development, as the application model project of industrial Internet deployment, predictive maintenance is expected to become one of the killer applications of IIoT (Industrial Internet of Things), especially the enabling of sensor technology and artificial intelligence algorithm, so that its practicality is greatly enhanced, and the prediction accuracy is also greatly improved. ADI Smart Motor Senor (SMS) is a good example of predictive maintenance product design."

How to accurately "pulse" motor health?

Industrial manufacturing equipment is becoming more efficient and intelligent, but the maintenance of the equipment itself is still a huge challenge. According to ISA data, the global manufacturers suffer a loss of $647 billion every year due to equipment failure downtime. Motor is known as the "mother of industry" and one of the main cores of modern industrial power source. Therefore, predictive maintenance for motor is an important topic in the industry, and also a hot technology focused by many head technology suppliers, including ADI.

In order to realize the widespread implementation of predictive maintenance, it is necessary to solve the two core problems of accurate prediction and effective diagnosis, and the high precision real-time data acquisition hardware scheme, advanced equipment digital model and diagnosis algorithm are just needs. The progress of sensing technology and the introduction of artificial intelligence technology accelerate the development process.

The state-based equipment monitoring, especially the realization of data diagnosis or predictable algorithm, has a lot to do with the equipment itself. The failure mode of different motors is completely different from the data matching method of the model. In industrial motors, bearing damage is a common fault in the process of use. Vibration and sound sensors are mostly used in detecting such faults, while rotor, winding and other faults are mostly detected by current transformer when the motor is supplied with power.

Therefore, in the "pulse" motor working state is healthy, need a large number of effective data support, such as pressure, vibration, noise, temperature and so on. According to the existing research and product development experience, vibration + temperature detection mode is a cost-effective solution that can effectively detect motor equipment anomalies, and the fault detection accuracy is also very high. ADI's smart motor sensor solution is a high-performance predictive maintenance platform based on AI designed for three-phase squirrel cage asynchronous motors.

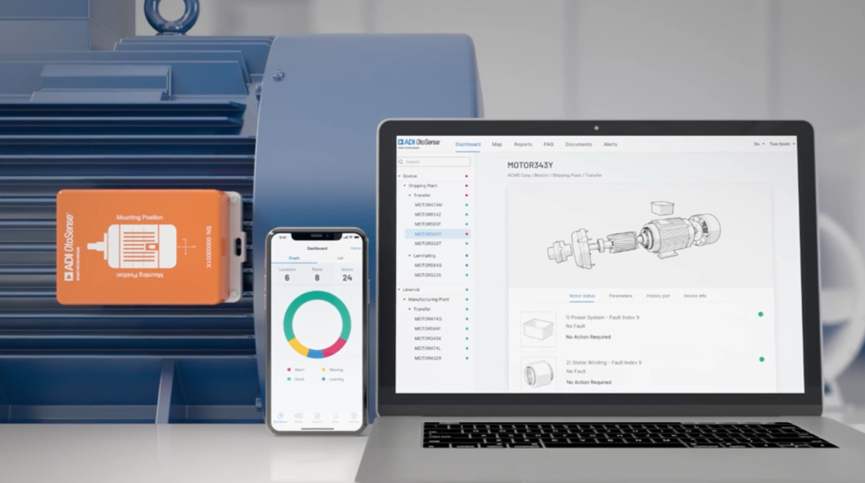

Powered by only four replaceable 1.5V AA lithium batteries, the SMS device integrates ADI high-performance sensors, precision transducers and signal chains to capture motor vibration, temperature, speed and flux to detect abnormal motor conditions at an early stage. And securely send that data over a Wi-Fi connection to a back-end cloud for processing. Ai engines running in the cloud and integrated into Web applications analyze data and monitor motor health, enabling customers to implement 7x24 hour motor health monitoring from mobile applications or PC-side network dashboards.

SMS combines ADI's software, hardware, and electrical expertise to create a secure and scalable product for predictive maintenance of electrical machines that is easy to set up and install, anytime, anywhere, no on-line or downtime, suitable for a variety of harsh industrial environments, indoors and outdoors.

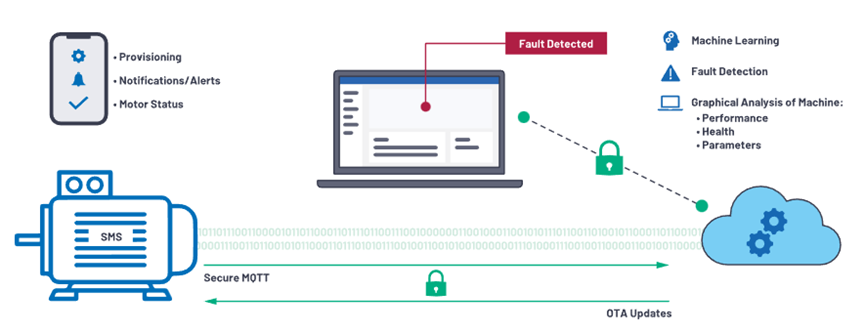

Schematic diagram of an end-to-end predictive maintenance solution for a motor

From sensors to cloud AI

ADI benchmarking high performance predictive maintenance solutions

The ADI Smart Motor sensor solution consists of data acquisition and communication hardware fixed to the motor heat sink, cloud-based software and algorithms, and client-side applications. Used with Android or iOS mobile applications, the sensors can be easily set up to provide visibility to deployed data. Its outstanding advantage in addition to the real-time monitoring of the running state of the motor such as switching times, running time, speed, current, output torque/power, etc., it can also diagnose the most 9 kinds of motor abnormalities in the industry, making the equipment operation and maintenance more intelligent and convenient.

ADI SMS Solution is capable of detecting the following 9 common problems as follows:

(1) Abnormal power supply: three-phase power supply failure (three-phase current imbalance), or three-phase power shortage.

(2) Stator anomaly: single-phase internal short circuit of the motor, insulation problem between coils, increase current and produce three-phase unbalance.

(3) Rotor anomaly: rotor damage, rotor material structure defects.

(4) Unbalance of machine shaft: uneven mass distribution, resulting in load deviation from the center of rotation; The rotor is bent.

(5) fixed rotor symmetry: dynamic may be due to shaft bending caused by the clearance change between the rotor and the stator; Improper installation of bearings leads to alignment problems inside the motor, causing clearance changes between the rotor and the stator.

(6) Bearing anomaly: mechanical stress or pollution will lead to small cracks or defects in bearings, resulting in vibration problems.

(7) Axis offset: when the two rotating axes (motor and load) are not aligned, the outside is not aligned, resulting in motor axis offset.

(8) Abnormal heat dissipation: It is suitable for motors cooled by external fans. The problem of fan connecting to shaft or external connecting to motor can be determined.

(9) Fixed anomaly: When the motor base or the connection with the motor base is not strong, there will be structural loosening, and this bad connection will lead to excessive vibration.

The high performance of the solution can't be achieved without the ability of hardware and software products. SMS hardware is embedded with five sensors, including two vibration sensors ADXL1002, two temperature sensors ADT7420, and ADI custom magnetic sensors -- the ADXL1002 has ultra-low noise and supports high broadband operation. Excellent performance in phase response, impact resistance and recovery; Two temperature sensors are used to detect the temperature difference between the environment and the motor surface. ADI's custom magnetic sensor can indirectly calculate part of the current signal of the motor by detecting the magnetic field intensity generated by the rotor rotation of the motor.

The vibration and temperature detection of the motor may be relatively routine, but with the ADI characteristic magnetic sensor, the mechanical signal, temperature signal and electrical signal are integrated into one, realizing the data fusion of multiple sensors. This is a unique feature of SMS solutions, and the wireless transmission of sensor-collected data to the cloud is another advantage of SMS, which avoids the limitations of laying out wired networks and enables quick and flexible installation and deployment in industrial sites.

On the other hand, as a predictable device maintenance system, the biggest benefit SMS can provide to customers is reliable monitoring of condition data and feedback of maintenance recommendations based on diagnostic results, due to the accuracy of monitoring motor health and analysis of SMS cloud AI engine data. Algorithm engineers are motor experts themselves, so they have a deep understanding of the motor system structure, driving principle and the external manifestations of motor faults. In addition, during algorithm development, ADI Laboratory also conducted a large number of tests for different types of motors with different power. Rich data accumulation is also an important guarantee to support the effectiveness of cloud AI platform fault diagnosis.

In fact, the advantages of powerful AI algorithm go far beyond that. Huo Bin also mentioned that when similar schemes of competitors are deployed, they usually need to manually set the relevant thresholds of motors according to the experience and testing of field engineers. If the load changes during operation, the thresholds need to be manually modified, which causes a lot of inconvenience and also requires very high level of related personnel. The ADI SMS solution takes full advantage of AI algorithms. Instead of manually setting thresholds, the system automatically calculates them during installation and dynamically adjusts them according to changes in equipment operating conditions, lowering the threshold for operators.